Enhance Your Home with 3 Oak’s Soundproofing Solutions

Living in the bustling city of London or anywhere across the UK means that creating a home environment holds great importance. By using 3 Oak’s soundproofing solutions, it will not only enhance the aesthetic appeal of your home but also provide a tranquil sanctuary where you can retreat from the hectic aspects of the outside world.

The Importance of Soundproofing, in Your Residence

In populated settings, especially in buildings with multiple occupants like apartment complexes, soundproofing is not merely a luxury – it is an essential requirement. Installing soundproofed flooring offers advantages such as ensuring you are in compliance with local building codes, enhancing the privacy boosting property value and significantly improving the overall living experience.

Compliance with Building Regulations

Within England and Wales, the Approved Document E of the Building Regulations outlines the criteria for noise insulation within properties. Adhering to these standards is vital. To prevent potential conflicts, we here at 3 Oak possess in-depth knowledge of these regulations with which we can provide expert assistance to ensure your property aligns with all guidelines. This is particularly vital in London’s mansion blocks and multi-story residential buildings. We encourage all our customers to review their lease and consult with their Building Management Company to understand the requirements of soundproofing.

Our Soundproofing Solutions

At 3 Oak, we’re skilled at blending soundproofing techniques with our wood floor installations. We recognise the significance of taking an approach that addresses both appeal and practical requirements. It’s important to note that our soundproofing services are exclusively available to customers who purchase our flooring products.

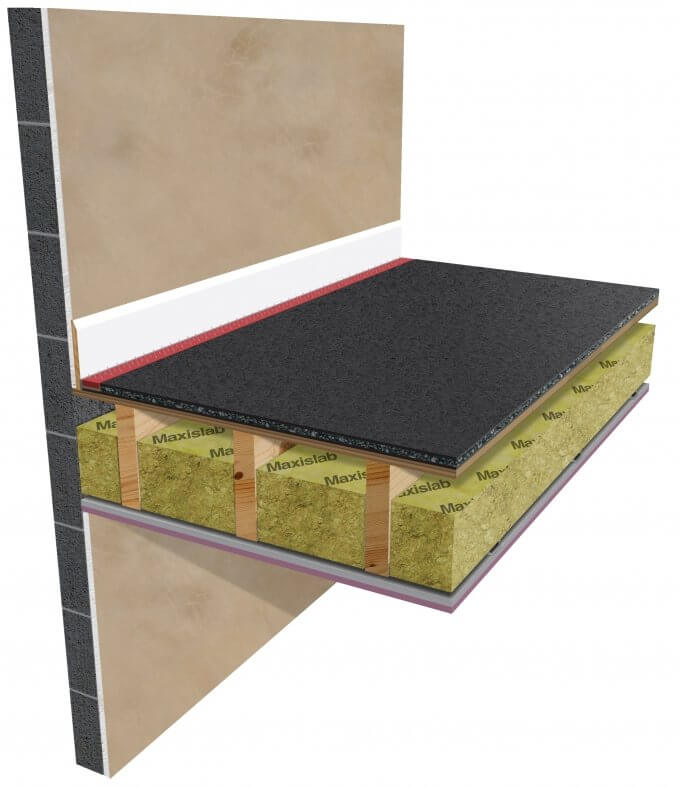

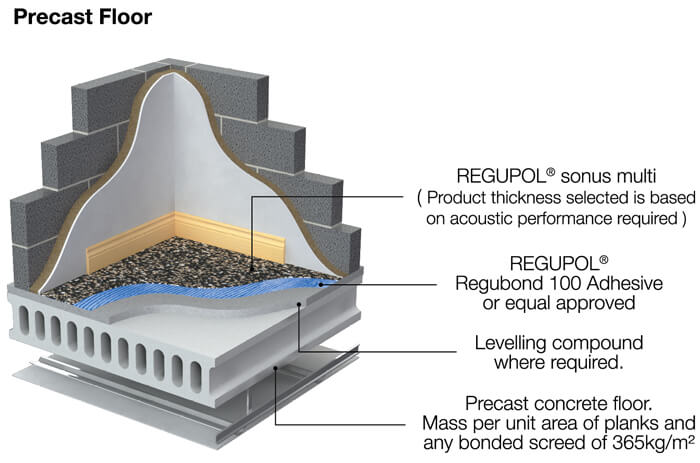

Choosing the Right Underlay

Selecting the underlay is essential for soundproofing. We collaborate with brands such as Regupol, Strata and Acoustilay to offer underlays that strike a balance between weight and flexibility. These materials are crafted to minimise impact noise, creating a clear sense of tranquility in your home. Our specialists will assist you in choosing the underlay that complements your selected flooring, ensuring it meets both your preferences and industry standards.

Privacy and Enhanced Property Value

Using proper soundproofing your when installing your floor will prevent the noise from travelling between rooms and floors as well as making your living area more private and serene. Additional soundproofing may contribute to the increase of the market value of your property. Both buyers and renters seek a peaceful housing option, particularly in busy locations such as London, which should make your property more desirable.

Why Choose 3 Oak?

- Professional Knowledge; With two decades of experience in this field, let our expertise steer you through the soundproofing journey while complying with all the relevant regulations.

- Quality Materials; We exclusively utilise materials and soundproofing underlays of remarkable quality which guarantee both the efficiency in reducing noise as well as the longevity of said efficiency.

- Tailored Solutions; We acknowledge that each household is unique which is the reason we provide customised consultations to discover the soundproofing option that matches your requirements.

Get in Touch

Are you ready to transform your living space into a serene and peaceful sanctuary? Contact us today to learn more about our wood flooring and soundproofing services. Let us help you enhance your homes value, comfort, and compliance with the highest standards of quality and professionalism.